“We built this city on Rock and Roll”

VELDHOVEN - blog #4 Monday 15 February 2021

In this fourth blog, Gerard talks among others about the sustainability of concrete.

In the background you can hear the music coming from the speakers in the factory halls. The same channel in all the halls, playing the same song: “We built this city on Rock and Roll”.

Music often works like a time machine and takes you back in time, with the sounds of the melody transporting you back to times gone by. In your working life there are many such moments, when listening to a song takes your thoughts back to the development of, at the time, a new product and the completion of another fantastic construction project.

The basic construction material, whose praise we sing from the rooftops here at Byldis Prefab: concrete!

In inner cities or a polder landscape you can always find something containing the composite material concrete. From the washed-out paving stones in your grandma’s front garden, to the ultra-thin UHPC beams of an eccentrically designed bridge component.

The many names carried by this material give shape to precast concrete, but a word like ‘sustainability’ can also be used to describe concrete. On one hand because it is almost indestructible and is by default designed to last 50 years, but can just as easily keep going for 100 to 200 years. Sustainable in the sense of reuse - circularity. From the recovery of all the raw materials used to make concrete into a solid mass and then placed in a precast wall, to the reuse of empty office units with smart precast re-design possibilities.

In terms of innovation, there are so many opportunities nowadays. This is why we are now inviting clients, architects, technicians and students to inspire us with their new designs. Concrete can always be used as the basis or as a component within a new project.

But filling the world with concrete blocks? No. The focus is on conscious construction based on breaking down old concrete blocks from the ‘60s and ‘70s that are no longer in use and repurposing the concrete chunks in the current concrete compositions. This is contradictory, because have I not just written that concrete constructions can last for 50 to 100 or even 200 years? Of course, and in fact it will because all these concrete chunks will be used in a new building that is expected to last an eternity. Just take a look at our slumbering throw-away society.

“But isn’t cement bad for the environment?”

The question came from a student at the Academie voor Bouwkunst. And there you are, with the cement-bound concrete tile you have just presented. She is right; cement is a binding material that uses a lot of energy to produce, possibly too much by modern standards. New solutions are being sought as we speak. But don’t forget that concrete was once introduced as a replacement for clay, wood, stone or steel construction components. There are plenty of studies that show that something like forestry and the energy required to create a steel beam also do not fit with the modern “everything must be biodegradable and green” mentality. The solution for one is the challenge of tomorrow. Challenges in continuing to make concrete attractive, in all its possible forms. There is always more possible that you might initially imagine. We have all been raised within the organisation as creative realists and therefore jump over the proverbial bar surprisingly often, to look at it from the perspective of a metaphoric high jumper. You never do this alone, but always together. This makes it a shared construction dream and not a nightmare, as long as we continue to speak out clearly about what we are and are not building up together.

There are cement substitutes – there are raw material substitutes - you can compose concrete differently. New kinds of cement with names like Belietrijk Portland cement, the creation of which use much less energy than the current Portland cement brick – yes, even without cement as binding material, but via alkali-activated binders that use reactive fillers to bind the sand and gravel together to form a solid mass, that also remains solid underwater. We never stop experimenting at Byldis. Looking for new opportunities together goes hand in hand with the economic and technical aspects of our business.

The gurus who preach thinking outside of the box are just trying to teach us to listen better to ourselves and others. Let’s look back in time for a moment:

It was a demonstration about concrete at a primary school - group 8 - at least 10 years ago. As school choices were being made for the future, the children’s parents had been invited to come and talk about their job to the class. A girl in the class wanted to know whether it was possible to use cherry stones to make concrete. I was already using stones (gravel) so why not cherry stones, or fruit stones. The cherry stone concrete was made, and we all laughed about it – many years later we are now seeing Biobased concrete being developed as a serious construction material, with the application of elephant grass, for instance. Biobased concrete; concrete with raw materials that can literally be harvested, just like potatoes.

Closer to the work floor and more recent are the words spoken by the environmental steering group at Byldis: “Mapping out our waste products, in both concrete factories, is just part of the housekeeping, but it starts with focusing on the prevention of waste production in the first place. And what can be done with the waste that is produced?”

Concrete waste does not exist because it can be seen as a raw material and the possibilities are researched and applied on the spot. The desalination container has been in use for just over a year now and its expansion is planned in the coming annual plan. Not only every material in the concrete mixture, but also the concrete element itself can give new added value to a completely “green” reality.

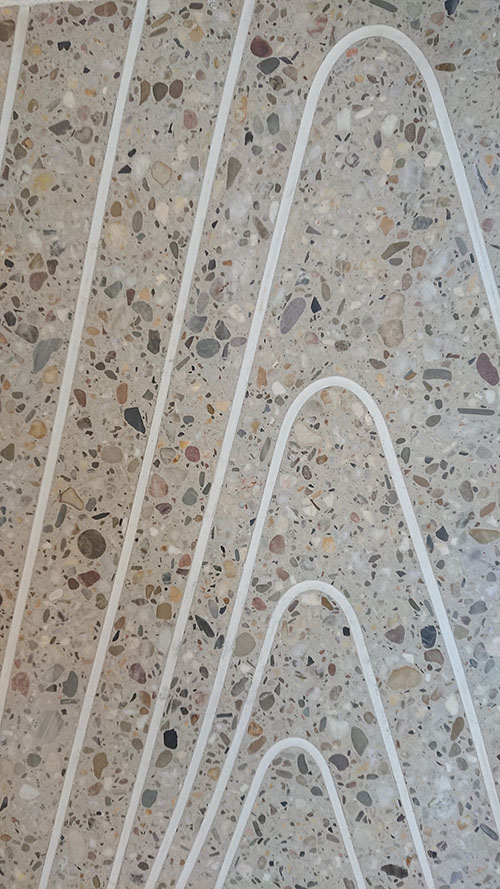

We like to look together at architectural concrete, and how great is it when you are able to use a completely different technique for bringing together waste products in one and the same concrete product? The application of a 3D printing technique for processing a non-concrete waste product, enclosed by a polished or non-polished concrete surface within the framework of a more environmentally aware mindset. After all, a photo says more than all my written words.

A concrete element is shaped through a process of steps. Pouring the concrete is just one step in the process. You make something that will be removed from the mould the following day and take it to the place it will remain for the following 50 to 100/200 years and more. Puzzle pieces that must all fit into place to make the whole, but that you already know can be taken apart again when the time is right to use them in a new puzzle.

The emergence of COVID-19 in the year 2020/2021 has imposed its own rules on building development. Working from home has become the norm and your office has become a kind of multifunctional clubhouse where you can occasionally look your colleagues/customers in the eye, under strict conditions of course.

In production environments, far-reaching automation has been created, whereby concrete is checked and processed using digital tests. Other times will follow, and other melodies will resound from the speakers in the factory halls. But believe me… the new generation of concrete will flow again as before and once more form the foundations of “The cities we are building”. Anyone who thinks that concrete belongs to the construction world of the past is seriously mistaken.

But wait... there's more!

In "Concrete chunks", Gerard Brood talks about his work as Senior Quality Officer and Concrete Technologist at Byldis. As well as a passion for his work, he also loves describing his observations. Want to read all the blogs? Go to: all concrete chunks.